© Copyright PMS GmbH. All rights reserved

The processing

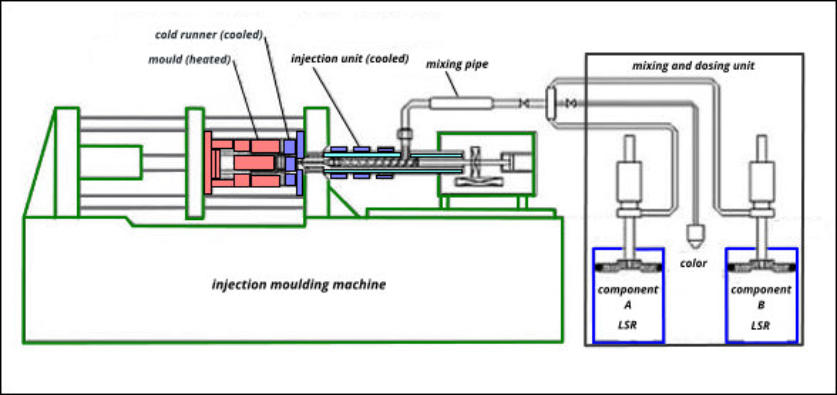

of LSR ( Liquid Silicone Rubber) with injection moulding :

Aspects of very economic LSR part production with LIM (Liquid Injection Moulding) :

- fully automatic process on slithly modified thermoplast- injection moulding machines

- very short cycle times

- highest part quality without any rework

- wasteless production with cold runner systems

- resource- and cost saving

- many possible combinations with other materials like thermo- or duroplast or many metals in one final part

The process „Liquid Injection Moulding (LIM)“

LSR-parts

are

being

made

with

heatetd

precision

moulds

on

sligthly

modified

thermoplast-

injection

moulding

machines.

After

the

2

Componets

(A+B)

Have

been

prepared

for

injection

by

the

mixing

and

dosing

machine

they

are

pumped

into

the

injection

unit

of

the

IM

machine.

The

material

than

gets

injected

into

the

mould

trough

special

cold

runner

systems

(-decks)

into

the

heatetd

mould.

Here

the

LSR

paste

cures

in

just

a

few

seconds

at

temperatures

of

140°C-220°C

to

a

rubber

like

consitency.

The

demoulding

of

the

parts

is

done

by

mechanical

ejectors, pressured air and / or linear handling systems or brushes.

Moulding technology for Liquid Silicone rubber (LSR)