© Copyright PMS GmbH. All rights reserved

You build your own moulds and are looking for a fully developed save and economic cold runner system ?

Our

cold

runner

systems

with

needle

valve

gating

technology

enable

a

troublefree

,

material-

saving

and

material-friendly

production

of

LSR-mouldings.

We

build

these

systems

as

a

standard

or

tailor

made

to

your

requirements

or

application

using

our

more

than

40

years

of

experience

in

this

field.

The

systems

can

be

adapted and adjusted to various moulds in order to be flexible and cost saving.

We build needle valve cold runner systems with 1 to 32 nozzles (depending on application).

The needle drive system can be hydraulik (standard), pneumatic or electronic.

Your advantages when using our cold runner systems:

- wasteless part production (no material loss for a cured hot runner)

- no rework on parts necesarry (removal of runners etc.)

- better part quality due to a material frienldy processing (low shear, no pre- curing)

- thermal stability even when processing fast curing material due to an eccelently adjusted cooling

- easy handling, cleaning

- low and easy maintanace

- simple replacement or exchange of parts like nozzle tip, nozzle, closing needle, seals etc

- realize different nozzle plung in depth (cold runner nozzle into the mould) by exchanging nozzles

- due to exchangable nozzle tips / needles you can realize different injection hole diameters using one system.

- due to the ability of nozzles beeing exchanged against plugs you can us a 16 nozzle cold runner system to feed

moulds with only 2, 4 or 8 cavities.

Needle valve cold runner systems

for Liquid Injection Moulding (LIM) of LSR ( Liquid Silicone Rubber)

Moulding technology for Liquid Silicone rubber (LSR)

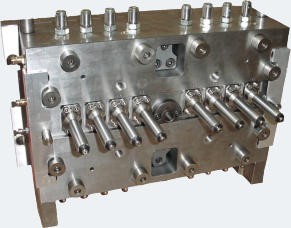

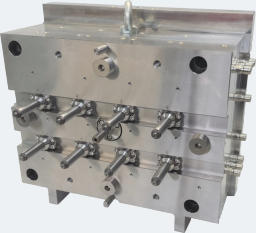

8 nozzle cold runner - 4+4 horizontal

8 nozzle cold runner - 4 horizontal

cold runner for intergation in 2C mould 4 +4 nozzles

12 nozzle cold runner - 6+6 vertikal

Exchangable

nozzle

tips

make

our

cold

runner

systems

very

flexible

in

use

and

applicationl

concerning

the

injection hole diameter.

Exchangable

nozzles

in

4

(act.5)

different

length

make

our

cold

runner

systems

very

flexible

in

use

and

applicationl

concerning

the plung-in depth (nozzle into mould).

Below you will find just a few examples of LSR cold runner systems that we have build for customers worldwide.

Flow-

trough

amount

for

each

nozzle

can

be

set

by

a

valve

(in

standard

system

-

hydraulik

needle

drive).

In

electrical

or

pneumatik

driven

systems

by needle way or opening- time.