© Copyright PMS GmbH. All rights reserved

We

design,

build

and

deliver

production

ready

injection

moulds

with

cold

runner

systems

for

the

processing

of

LSR

(Liquid

Silicone

Rubber).

These

moulds

are

high

perfomance

moulds

and

have

to

be

build

in

highest

quality

and

precision.

Talking

about

working

precisely

this

means

less

than

0,005mm

of

gaps

allowed

in

the

parting

line

in

order

not

to

have

any

flesh

on

the

parts.

Our

mould

systems

are

optimized

for

the

LIM

(Liquid

Injection

Moulding)

process.

On this page we are showing only some examples of the moulds we have already build for cutomers worldwide.

These moulds are producing millions of parts for industries like:

Baby care Medical Electronics Automotive Sanitary Houshold Leisure

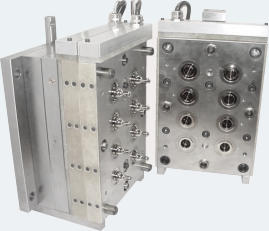

Pictures on the left are showing the injection moulds => on the right the LSR parts that are made with it.

Injection moulds for LSR (Liquid Silicone Rubber)

Moulds with cold runner systems for LIM (Liquid injection moulding)

injection mould for LSR baby soothers / pacifiers - 8 cavities

Moulding technology for Liquid Silicone rubber (LSR)

LSR baby soothers / pacifiers

injection mould for LSR baby bottle valves - 6 cavities

LSR baby bottle valves

LSR baby bottle nipples

injection mould for LSR baby bottle nipples - 8 cavities

injection mould for LSR overmoulding electronical connector part

LSR overmoulded electronical connector part (rib sealing)

injection mould for LSR overmoulding automotive brushcard

LSR overmoulded automotive brushcard (several sealings)